Innovative Application Trends of New-Generation Gear Motor Selection in Automotive Parts

The automotive industry is undergoing a period of profound transformation, fueled by electrification, autonomous driving, and a growing emphasis on fuel efficiency. These trends are directly impacting the design and performance requirements of critical automotive components, particularly gear motors. Traditional gear motors are increasingly giving way to new-generation designs offering enhanced efficiency, compact size, improved reliability, and advanced control capabilities. This article explores the innovative application trends driving the selection of these new-generation gear motors in modern automotive parts, incorporating insights into current automotive industry dynamics and future prospects.

The Electrification Revolution: A Key Driver

The shift towards electric vehicles (EVs) is arguably the most significant factor influencing gear motor selection. Electric drivetrains rely heavily on efficient power transmission, and gear motors play a vital role in various applications, including:

- Electric Power Steering (EPS): EPS systems leverage gear motors to provide variable steering assistance based on driving conditions. New-generation gear motors with higher torque density and improved thermal management are crucial for delivering responsive and reliable steering, especially in high-performance EVs. The demand for smoother, more precise steering is a direct result of the increasing complexity of autonomous driving features.

- Power Windows and Sunroofs: While seemingly simple, these systems still require robust and efficient gear motors. New designs focus on minimizing energy consumption to maximize driving range.

- HVAC Systems: Gear motors drive fans and compressors in heating, ventilation, and air conditioning (HVAC) systems. Improved efficiency in these motors contributes significantly to overall EV energy efficiency.

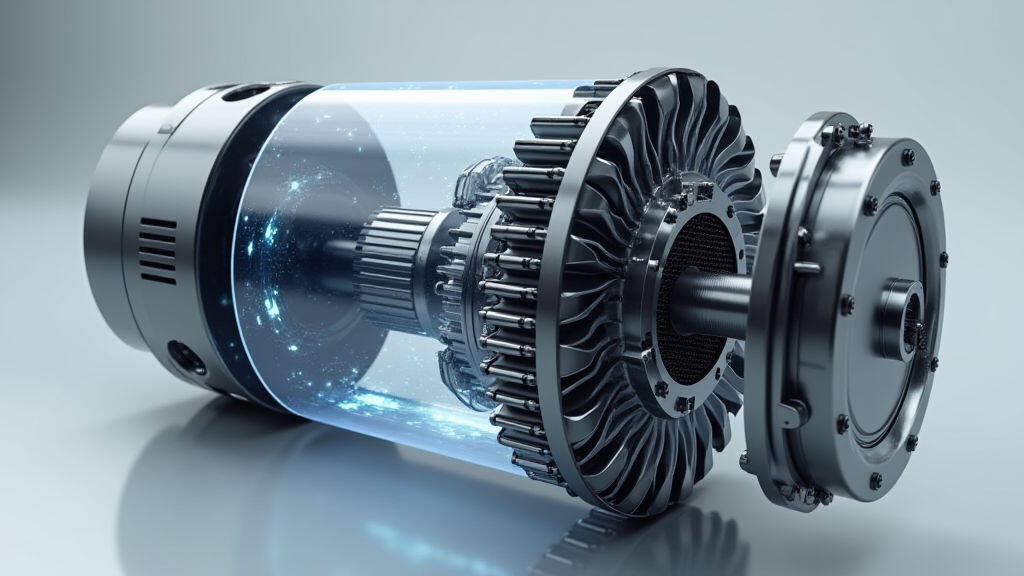

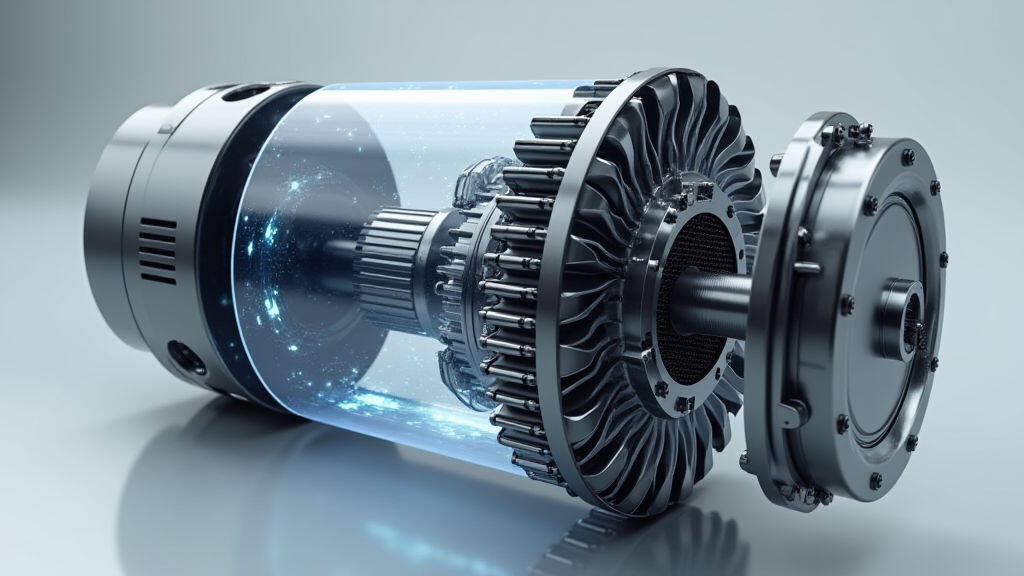

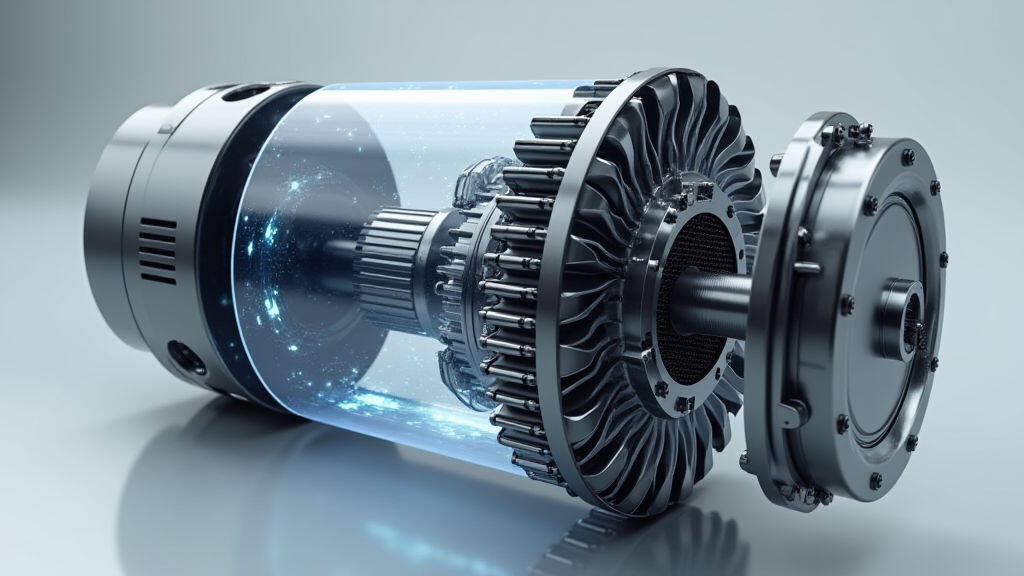

- Gearboxes for Electric Motors: In some EV architectures, gear motors are directly integrated within the electric motor, optimizing space and reducing mechanical complexity.

Autonomous Driving: Precision and Reliability are Paramount

The rise of autonomous driving demands gear motors that offer exceptional precision, reliability, and responsiveness. These motors are incorporated in:

- Active Suspension Systems: Autonomous vehicles require sophisticated suspension systems that dynamically adjust to changing road conditions. Gear motors provide the necessary power and control for active dampers and ride height adjustments.

- Braking Systems: Electronic Stability Control (ESC) and Anti-lock Braking Systems (ABS) rely on gear motors to control brake calipers with high precision, contributing to enhanced safety.

- Camera and Sensor Positioning: Autonomous vehicles rely on a network of cameras, radar, and lidar sensors. Gear motors are used to precisely position these sensors for optimal data acquisition, and the demands on motor precision are constantly escalating.

Compact Design: Space Optimization in Vehicle Architecture

Modern vehicle designs prioritize space optimization. New-generation gear motors are typically characterized by their smaller form factor while maintaining or even improving performance characteristics. This miniaturization is achieved through advancements in:

- Miniaturization of Components: Improved manufacturing techniques enable the creation of smaller gears, shafts, and housings.

- Integrated Designs: Some manufacturers are developing gear motors with integrated control electronics, thereby reducing the overall system size.

- Advanced Materials: The use of lightweight materials, such as aluminum alloys or composites, contributes to overall weight reduction and space savings.

Increased Efficiency: Reducing Energy Consumption and Emissions

Fuel efficiency (or energy efficiency, in the case of EVs) remains a central concern for automakers. New-generation gear motors are engineered for significantly improved efficiency through:

- Reduced Friction: Advanced lubrication technologies and improved gear designs minimize friction losses.

- Optimized Gear Ratios: Precisely calculated gear ratios maximize power transfer and minimize energy waste.

- Electronic Motor Control: Sophisticated electronic controllers optimize motor operation for specific driving conditions, maximizing efficiency and responsiveness. MES-Drive, for example, utilizes advanced algorithms to dynamically adjust motor parameters based on real-time vehicle data, improving energy efficiency by as much as 15%.

Advanced Control and Connectivity: Enabling Smart Vehicle Functionality

Connectivity and intelligent control are key aspects of modern automotive systems. New-generation gear motors are increasingly equipped with:

- CAN (Controller Area Network) Integration: This enables seamless communication with the vehicle's central control unit, allowing for coordinated operation with other systems.

- Sensor Feedback: Integrated sensors provide real-time data on motor speed, torque, and temperature, enabling proactive fault detection and predictive maintenance.

- Wireless Diagnostics: Wireless connectivity allows for remote diagnostics and over-the-air updates, improving system reliability and reducing maintenance costs.

The Role of Materials Science and Manufacturing Technologies

Significant advancements in materials science and manufacturing processes are underpinning the development of new-generation gear motors. These include:

- Advanced Gear Materials: The use of high-strength, wear-resistant materials like specialized steel alloys extends the lifespan of gear motors and improves their performance under demanding conditions.

- Additive Manufacturing (3D Printing): Additive manufacturing techniques are enabling the creation of complex gear geometries that are difficult or impossible to produce using traditional methods. This allows for optimized designs and improved performance.

- Surface Treatments: Advanced surface treatments provide enhanced corrosion resistance and reduce friction, increasing motor reliability and longevity.

MES-Drive: Pioneering Innovation in Gear Motor Technology

MES-Drive is at the forefront of developing and implementing these innovative gear motor technologies. They specialize in designing high-performance, energy-efficient gear motors for a wide range of automotive applications. MES-Drive's commitment to research and development, combined with their focus on advanced manufacturing techniques, allows them to provide cutting-edge solutions that meet the evolving needs of the automotive industry. Their proprietary motor designs consistently outperform competitors in terms of torque density, efficiency, and reliability. They also offer customized solutions tailored to specific vehicle requirements.

Conclusion: A Future Powered by Efficient Gear Motors

The selection of new-generation gear motors in automotive parts is driven by a confluence of trends – electrification, autonomous driving, space optimization, and the relentless pursuit of efficiency. These advancements are profoundly shaping the future of the automotive industry, leading to vehicles that are safer, more efficient, and more intelligent. As the automotive industry continues its rapid evolution, the role of innovative gear motor technology will only become more critical. Companies like MES-Drive are poised to lead the charge, driving innovation and enabling the next generation of automotive excellence. With the market projected to experience a CAGR of over 10% in the coming years, the demand for these advanced gear motors is expected to surge, solidifying their position as essential components in the future of mobility.

Leave A Reply

Your email address will not be published. Required fiels are marked